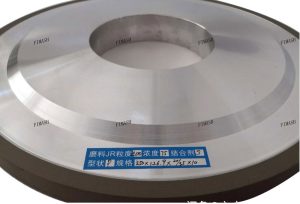

Category: Diamond/CBN Wheel

Peripheral sandlasting Wheel

Peripheral Diamond Grinding Wheel is mainly used for peripheral grinding of indexable inserts made of tungsten carbide, ceramics, cermets and CBN.

Send us email

sale@fimash.com

Call us

+86 13584178601

Advantages of peripheral grinding wheel

1. Good surface accuracy retention

2. High stock removal efficiency

3. Unique cutting edge quality

- Brazing process

- Electroplating process

- Sintering hot pressing

- process High cost

- performance Complete

- production packaging and delivery

Product Inquire Now

"*" indicates required fields