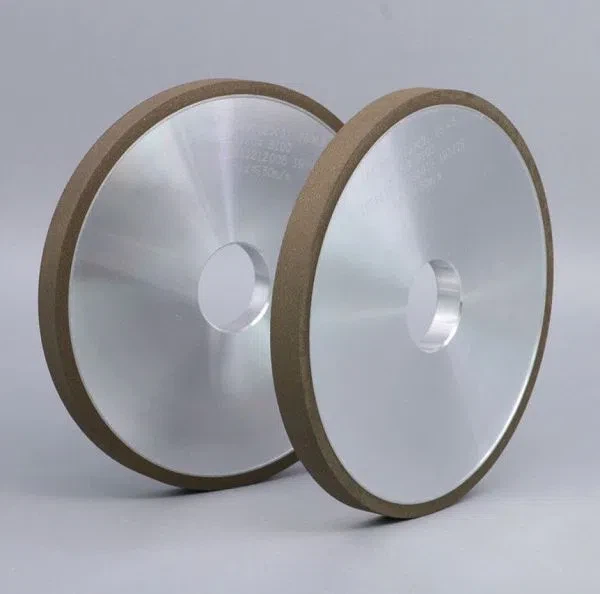

Using diamond abrasive as raw material, metal powder, resin powder, ceramic and electroplating metal are respectively used as binders, and the circular bonded abrasive tool with a through hole in the center is called diamond grinding wheel (alloy grinding wheel).

Classification Of Diamond Grinding Wheels

Diamond grinding wheels can be divided into: resin bond diamond grinding wheel; ceramic bond diamond grinding wheel; metal bond diamond grinding wheel (bronze bond diamond grinding wheel)

According to the production process, diamond grinding wheels can be divided into: sintered diamond grinding wheels (resin bond diamond grinding wheels; ceramic bond diamond grinding wheels; metal bond diamond grinding wheels); electroplating diamond grinding wheels; brazed diamond grinding wheels.

According to the grinding method, diamond grinding wheel can be divided into: diamond grinding wheel for grinding diamond; diamond grinding wheel for grinding carbide (diamond knife grinding wheel); diamond grinding wheel for grinding diamond composite sheet; centerless grinding diamond grinding wheel for coreless grinding machine; grinding ceramic products Use diamond grinding wheel; diamond grinding wheel for cutting (also known as diamond cutting blade); diamond saw blade.

Diamond grinding wheels can be divided into: parallel grinding wheels; cylindrical grinding wheels; cup-shaped grinding wheels; bowl-shaped grinding wheels; disc-shaped grinding wheels; edging grinding wheels; grinding discs, etc.

Structural Characteristics Of Diamond Grinding Wheel

The structure of diamond grinding wheel is different from that of ordinary abrasive grinding wheel. Generally, it is composed of diamond abrasive layer, transition layer and matrix.

The working layer, also known as the diamond layer, is composed of abrasives, binders and fillers, and is the working part of the grinding wheel. The transition layer, also known as the non-diamond layer, is composed of binder, metal powder and filler, and is the part that firmly connects the diamond layer to the substrate.

It is used to accept the abrasive layer, and is firmly clamped on the main shaft of the grinder with a flange plate when in use. Generally, the metal bond products use steel and alloy steel powder as the base; the resin bond uses aluminum alloy and bakelite as the base.

Made of aluminum, steel or bakelite, it supports the working layer and holds the abrasive tool. The quality of the grinding wheel forming and the accuracy of the use have a lot to do with the matrix.

Diamond grinding wheel is a super-hard abrasive grinding wheel. Compared with ordinary abrasive grinding wheel, it has very obvious features and advantages:

1. The hardness of the diamond abrasive determines the main characteristics of the diamond grinding wheel, which can efficiently grind hard-to-machine materials such as cemented carbide, glass, and ceramics, and the grinding tools have the longest service life.

2. Diamond has high wear resistance, the grinding wheel wears less, and the use time is longer. During the grinding process, the size, shape and morphology of the diamond abrasive grains change little, which is more suitable for high-precision machining and production efficiency. High, diamond grinding wheel is a tool that can satisfy both high efficiency and precision machining.

3. The sharpened diamond grinding wheel can maintain the micro-edge of the abrasive grains for a long time, and the good cutting performance ensures a small grinding force during the grinding process, thereby reducing the grinding power and saving energy.

4. The thermal conductivity of diamond is very good, which is conducive to the evacuation of heat, avoiding the phenomenon of workpiece burns, cracks and falling blocks, which greatly improves the quality of workpiece surface processing.

The Use Of Diamond Grinding Wheel

Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels have become the ideal tool for grinding hard and brittle materials such as glass, ceramics, gemstones, stone, and carbide.

With the progress of the times, the development of science, the needs of society, the development of new materials, and the continuous development of grinding processing in the direction of high quality, high precision, high efficiency and automation, the role of diamond grinding wheels is becoming more and more obvious.

The diamond grinding wheel has high holding strength for abrasive grains, long life and low wear, so that the diamond grinding wheel can give full play to its strong wear resistance and cutting ability in high-speed and ultra-high-speed, high-efficiency and high-precision grinding, especially in hard, brittle and difficult machining. The material shows its obvious advantages and is widely used.

Diamond grinding wheels are used in almost all sectors of industry, such as aerospace, mold manufacturing, semiconductor manufacturing, and optical processing manufacturing. Ceramic materials, optical materials, aero-engine turbine blades, silicon wafer products, etc. are mostly ground with diamond grinding wheels.

Precautions During The Use Of Diamond Grinding Wheels.

Side grinding problem

In the daily use of grinders, we can often find that some operators arbitrarily use the side of the grinding wheel to grind regardless of the type of grinder or the type of grinding wheel, which is an illegal operation that seriously violates the safety operation regulations behavior

The grinding wheel that uses the circumferential surface as the working surface according to the regulations should not use the side surface for grinding. This kind of grinding wheel has high radial strength and low axial strength. If the operator exerts too much force, the grinding wheel will be broken and even hurt people. In practice, This behavior should be prohibited during the use of.

Frontal operation problem

In daily use, many operators are always accustomed to operating in front of the grinding wheel, because the force can be used in this direction.

In fact, this behavior is a behavior that should be specially prohibited in the operation of the grinding machine. According to the operating rules, when using the grinding wheel machine to grind the workpiece, the operator should stand on the side of the grinding wheel and not operate on the front of the grinding wheel, to avoid the grinding wheel flying out or the grinding wheel breaking and flying out and hurting people when the grinding wheel fails.

Force operation problem

When using the grinder, some operators, especially young operators, use too much force in order to grind faster, which is an extremely unsafe operation behavior.

The flat body of any grinding wheel has a certain strength. Doing so may cause the grinding wheel to be broken, or even fly out and hurt people, which is also a prohibited behavior.

Common operational issues

In the actual daily operation, there is also such a situation. In order to rush production tasks and work time, two people share a grinder to operate at the same time.

This is a serious illegal operation and should be strictly prohibited. When a grinder is not enough, it can be solved by adding a grinder, and it is absolutely not allowed to share a grinder at the same time.